Acuros Camera Family

The Acuros camera family features InGaAs equivalent noise, pixel operability greater than 99%, 15µm pixel pitch, and three different pixel array sensor formats (640×512, 1,280×1,024, and 1,920×1,080). The cameras are capable of imaging at speeds up to 380fps via GigE Vision and USB3 Vision. The HD camera’s 2.1MP are 6.3 times higher clarity than today’s InGaAs VGA cameras, providing users with richer imaging detail. The 1,920×1,080 high density arrays have pixels with 6 times smaller area than 640×512 VGA cameras directly improving spatial resolution and defect detection. The CQD SWIR camera sensors fabricated with low cost materials and CMOS-compatible fabrication techniques represent an advance towards broadly accessible high definition SWIR imaging. It is expected that the camera’s lower cost points and its non-ITAR, EAR99 export classification to drive higher adoption rates globally, broadening the market for SWIR camera technology.

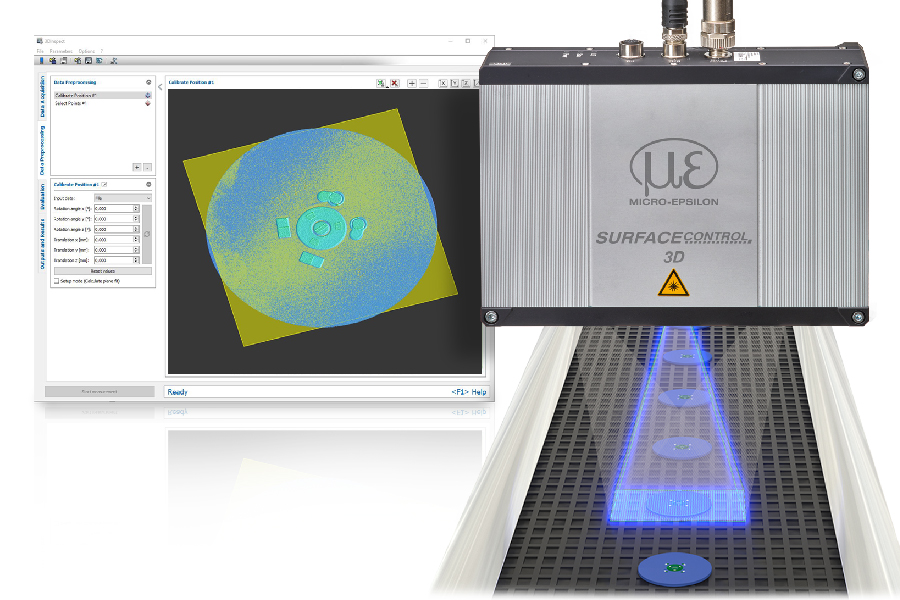

Applications

Silicon wafer inspection is an important application that can clearly leverage this new capability to see smaller features. The CQD cameras can be used to illuminate silicon wafers for: identifying front-to-back alignment marks, detecting voids in bonded wafers, imaging of for backside dicing, visualizing and detecting sub-surface cracks, and inspecting wafers for buried features, to name a few. Vision systems designed to inspect solar cells, glass bottles, and hosts of other industrial parts will now also see more. This higher resolving power can also be used to broaden the field-of-view, where machine vision cameras may now be configured to image both small and large format objects at the same imaging distance, with superior spatial resolution. Additional applications for the CQD cameras include: accurately identifying fill levels of transparent and opaque containers, inspection of embedded electronics, detection of moisture levels in packaged products, thickness and void detection on clear coat films, glass bottle imaging, bruise detection in fruits and vegetables, inspection of lumber products, detection of water/oil on metal parts, chemical analysis, imaging through smoke and mist environments, surveillance and security monitoring, crop monitoring, glucose monitoring and many more.