Seeing Robots

Smart camera for Robotic Vision Guidance Platform

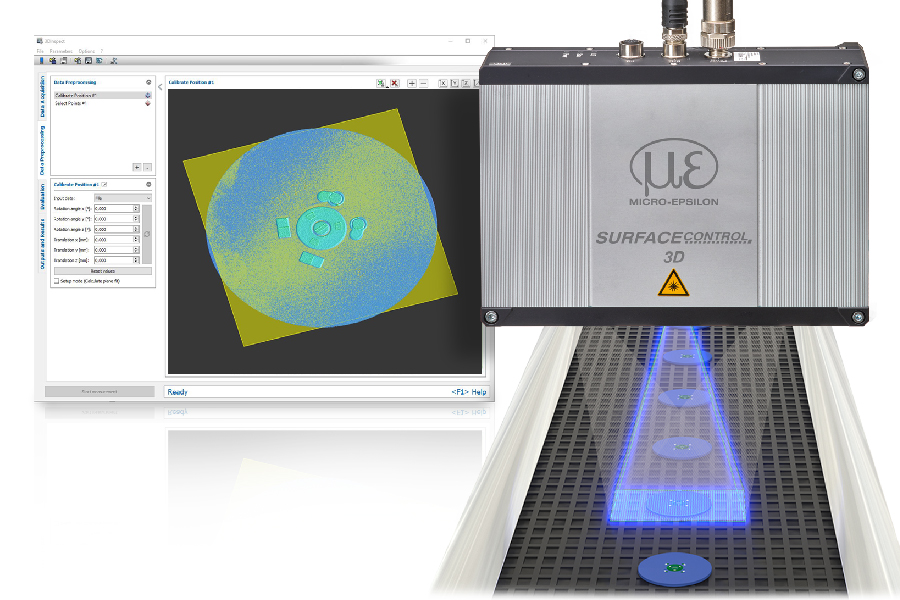

Recognition Robotics is able to use their visual recognition system to guide any robot to pick-up and place complex objects using a single robot mounted smart camera.

Image 1 | Accurate part information from a 2D image with CortexRecognition and the Neon 1020 smart camera, which has an Intel Atom Quad-Core Processor E3845 1.91GHz, a FPGA co-processor and weights less than 2kg. (Figure: Adlink Technology Inc.)

Recognition Robotics is a technology leader for visual recognition and robotic guidance. They have eleven patents which cover the capability to locate a part and determine six degrees of freedom from a single 2D camera image. As a result, the company is able to use their visual recognition system to guide any robot to pick-up and place complex objects using a single robot mounted smart camera. Today, Recognition Robotics has found success with over 300 systems deployed in applications, such as automotive body-in-white deracking applications, automotive powertrain and airframe fastening. The vision solution is simple to train and set up, and is able to use a single camera to acquire all of the information necessary for robot guidance. In 2012, Recognition Robotics went to market with their initial product called the Robeye, a solution for robotic guidance. The core differentiator of Robeye is visual recognition and guidance software that mimics the way humans see. „The algorithms are based on the human cognitive ability to recognize objects. When I developed these algorithms, I was mimicking the human visual cortex. We’ve used knowledge about human brain function, the point of view of the human eye, and put this into the software realm.“ describes Dr. Simon Melikian, CEO of Recognition Robotics, the advantages of the Robeye software. Robeye uses an industrial camera attached to the robot arm to take images of the robot workspace, and a separate industrial computer to process the images and communicate with the robot’s controller. From a single 2D image the system is able to recognize a part and return the x, y, z, Rx, Ry and Rz location information about the orientation of the part within the robot’s user frame. With this data, the robot is then able to update a preprogrammed path with the corrected offset data of that parts current location in space.