What will be the difference between the classic metrology system and an IIoT metrology system? Dr. Michael Nahum (Mitutoyo): Well, classic metrology really is typically a go/no-go kind of gauging system where the operator writes the measured data on a piece of paper. And you’d be surprised that we have some very sophisticated customers, including in the semiconductor industry, that still do that. On the other hand, IIoT is digital. It’s a blending of information technology with operational technology.

Dr. Kai-Udo Modrich (Zeiss): The main point is that in the past we had metrology experts standing in the measurement room, understanding all these figures on a measurement report and they were able to explain the production people if they produced correct or if they didn’t produce correct. But for the production there was no targeted visualization available. So with all the possibilities that come along with IIoT and with the visualization of data it completely changed the interaction between the quality area and the production area. There has always been a fight between quality and production: Production wants to produce the highest number and the quality is looking if the quality is correct and the quality department is looking for the best quality.

Johannes Mann (Hexagon): I would say IIoT device makes the data available for everybody who is a stakeholder of the data. So IIoT makes it possible for the whole production chain to take the dimensioning and turn it into a valuable asset for the production.

Nahum: Now we also have massive amounts of data that are available to us. And thankfully, now you can perform all kinds of analytics with AI and machine learning and really look for trends in your production. That’s something that until recently has not been available, so this is a massive shift I think.

Does everyone of you have these tools to analyze these amounts of data already and what will be the next steps they can do with this data?

Mann: I think the first step which we are doing now is connecting the data with the production processes. You gather tendencies and put them into relation about your processes and AI will support you with that.

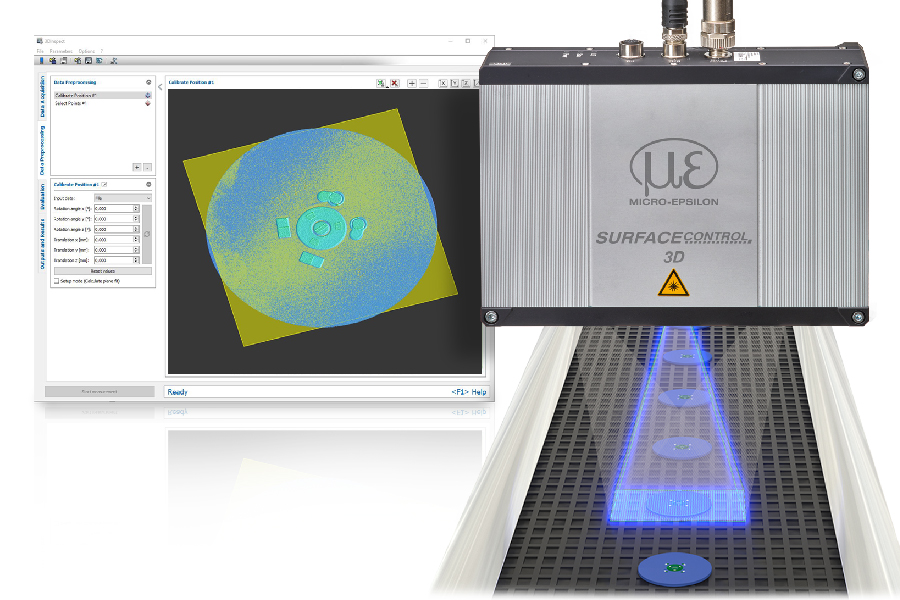

Modrich: I think it’s important that we make the difference between process control and real metrology. Also, what is the need of the customer and what can we provide as metrology companies and what is the goal for the future. So first of all it must be clear what kind of data we are collecting and that they are comparable. The second aspect is to determine what kind of closed loop you are looking at. A quality closed loop or a production closed loop. If you have a quality closed loop then you’re in the field of metrology. So you have to fulfill all the requirements and standards that are given in Metrology. For process control in production we steer the manufacturing processes based on the acquired quality data.

How can standardization support the utilization of metrology and what standards we’re talking about?

Modrich: Standardization enables the possibility to collect data from different devices, make them comparable and use them for steering the smart factories of the future. On the shopfloor, on the edge or even in the cloud. A clear IT structure with standardized interfaces to exchange data through all layers is cruical for an efficient use of the measurement data. This is the first thing about standards, interfaces and exchanging data. The second is standards in metrology. For example everybody in metrology knows the ISO10360. These are given rules and standards how we have to process the metrology devices in the metrology lab. Now we have to look if these standards can also be applied in the production environment and we have to adapt them to the different applications.