Camera & Lighting Enclosures

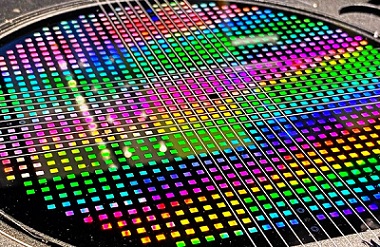

Depending on the setting, machine vision components can be exposed to harsh elements such as corrosive chemicals, high temperatures, and water submersion. Putting these components into ruggedized enclosures protects them from the elements and maintains system reliability. Enclosures house cameras and/or light sources in sealed metal shrouds are usually aluminum or stainless steel. Many enclosures often also feature a protective window, which allows the camera to see out, doesn’t interfere with image quality and serves as a protective barrier. Choosing the correct window material for the environment is key to providing adequate protection while keeping costs low. For example, light weight and shatter-resistant acrylic is ideal for food-grade / FDA-compliant applications. Acrylic provides an easy-to-clean surface while minimizing the risk of falling shards if the window was to be subjected to impact. For harsher environments, glass windows are the optimal choice, as additional options are available for impact, scratch and heat resistance.

Custom Solutions

Some vision systems may require a custom protective window to fit the design or application requirements such as autonomous mobile robots or drones for aerial landscape imaging. Custom options include:

- Silk Screen Printing in a variety of colors and opacities for printing borders, masks, logos and other information. Inks that can act as optical longpass filters are also offered. (Ex: ink that blocks visible light but passes NIR light.)

- Chemical Strengthening for applications where the glass is placed in front of a camera lens and optical distortion and surface quality are important. It’s ideal for thinner glass (less than 3mm thick) and is most commonly used for Gorilla Glass, soda lime glass, some filter glasses and B270 and BK7 glasses.

- Thermal Tampering/Heat Strengthening is offered for glass that exceeds 3mm in thickness to improve resistance to impact (up to eight times), high temperatures and scratches.

- Assembly Mounting Tapes for easy assembly when screws are not an option. Very high bonding (VHB) tape is an easier and more convenient option than difficult to work with cements or liquid adhesives.

- Specialized Shapes and Sizes can be precision cut to fit a specific radius or hole.

www.midopt.com