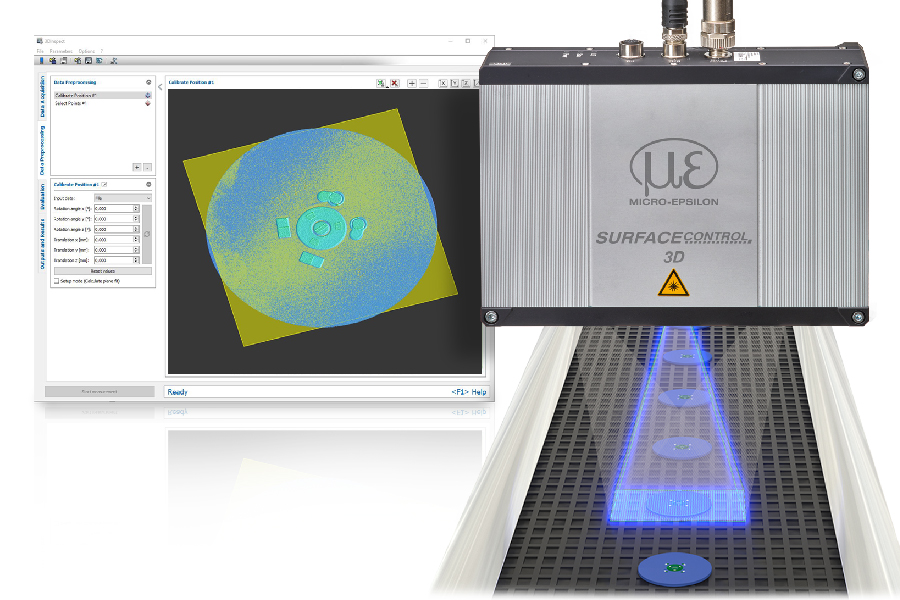

The challenge was to measure both sides of the Audi e-tron BIW in a narrow space, with one robot, one sensor, and one turntable. The need was for a solution that could provide accurate and reliable data quickly and efficiently, ensuring the highest quality in their measurement processes. Eleven Dynamics stepped in with a solution. They implemented Nexos 4.0, a software that could simulate the problem and find the perfect cell layout. This solution was capable of supporting any robot, any sensor, and any cell configuration, making it a perfect fit for the diverse range of tasks in their measurement services.

The solution was flexible and adaptable, designed to meet Audi Sport’s specific needs. It could support any robot, any sensor, and any cell configuration, making it a perfect fit for the diverse range of tasks in their measurement services. The results were impressive. The Nexos 4.0 and the simulation significantly reduced the complexity of the measurement process, providing accurate and reliable data quickly and saved 85% of the processing time. The solution also implemented automation in their processes, enhancing their measurement services. The solution demonstrated the added value in real-time, convincing Audi Sport of its effectiveness. As a result, measurements are absolutely compensated automatically in Nexos 4.0 and data is streamed directly to Polyworks. Another advantage of the software is, that engineers and operators don´t need to be retrained every time with new software.

Conclusion

The successful implementation of Nexos 4.0 and the simulation at Audi Sport shows the power of Eleven Dynamics‘ solutions. The adapted solution driving companies from manual metrology, to semi-automatic metrology (atline), to fully automated metrology (inline) in a painless process.

www.11dynamics.com