Prior to automation, beef scribing was a skilled manual task fraught with risks and inefficiencies. Operators were using heavy and hazardous circular cutting saws to perform intricate cuts on high-value beef carcasses, facing the constant threat of injury and the potential for inaccuracies in the process. Recognizing the need for a safer, more accurate solution, Intelligent Robotics Pty Ltd, with the support of AMPC’s investment into advanced manufacturing, embarked on a mission to revolutionize beef scribing through automation.

Game-changing solution

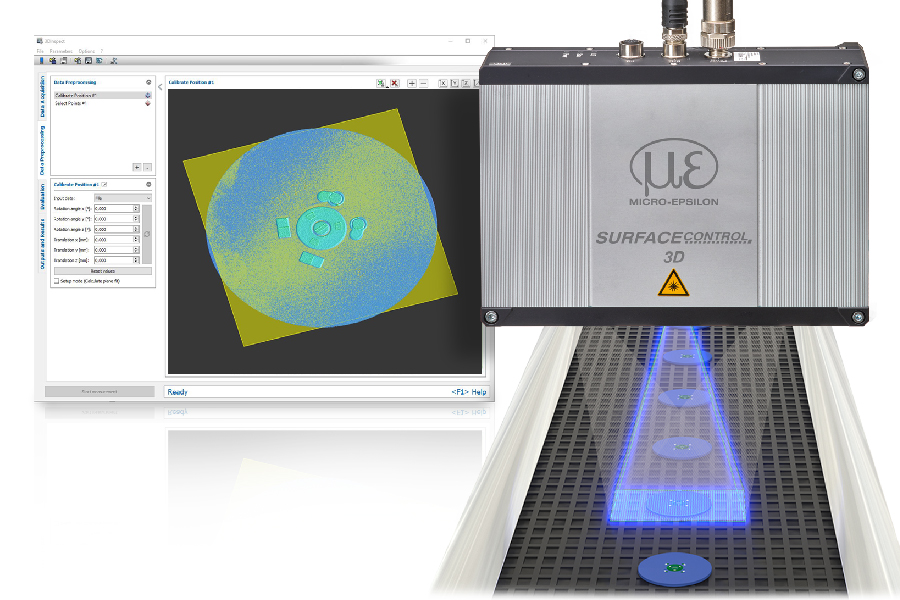

IR-Scribe is an AI-driven automated beef scribing system that leverages the power of Photoneo’s MotionCam-3D. Installed at Kilcoy Pastoral Company’s processing plant in Queensland (Australia), IR-Scribe represents a paradigm shift in beef processing technology. The system uses a circular saw attached to a robotic arm to cut through rib cages and bones. Prior to the commencement of cutting, each side of beef undergoes scanning by a series of MotionCam-3D cameras. The camera´s proficiency in capturing accurate 3D point cloud images is particularly notable amidst the dynamic movement of beef carcasses hanging on conveyor racks. Because the camera effectively resists the effects of movement and vibrations, it ensures unmatched precision in identifying key features of interest on each carcass. The 3D camera provides a resolution of 2MP, sub-millimeter accuracy, detailed contours, and high robustness even when scanning varying sizes and shapes of the scanned beef sides. After scanning, advanced vision processing and AI algorithms come into play, analyzing the 3D images to identify key features on the carcass that define precise cut locations for robotic incisions. The first robot performs one of the spine cuts and then moves out of the way to allow the cameras to capture another image and recalculate the location of the second cut. „This is actually quite important because this re-fixturing of that second cut is what enables us to ensure that even with slight movement from performing the first cut, millimeter accuracy is maintained,“ explains Jonathan Cook, Electrical Engineering Manager at Intelligent Robotics. The carcass then proceeds through the cell, passing another series of cameras before reaching the second robot. Here, it undergoes a similar vision processing procedure, this time to determine the locations for two vertical rib cuts. The robot then performs the cuts and the carcass exits the cell.

Delivering tangible benefits

The benefits of this novel beef cutting technology extend beyond increased accuracy and efficiency. The system enhances worker safety as it replaces manual cutting operations with heavy saws. Additionally, by enhancing yields and ensuring more consistent scribing operations, the technology maximizes the value extracted from each carcass, leading to substantial cost savings. The unique beef cutting technology is spearheading a transformative shift in agriculture, where safety at the workplace and efficiency in production are paramount concerns. MotionCam-3D’s capabilities to 3D scan in motion help contribute to increased food production efficiency and to addressing global food production challenges. „Photoneo’s 3D vision technology enables maximum labor safety and grants highest yield. Unmatched precision of cuts, enhanced quality control, and optimized processing procedures minimize waste,“ says Werner Müller-Veith, CEO of Photoneo.

Summary

The introduction of IR-Scribe marks a pivotal moment in the beef processing industry. As the demand for automation and advanced technology continues to grow, solutions like IR-Scribe are leading the charge towards a future where safety, efficiency, and quality converge seamlessly, setting new standards for beef processing excellence. As Jonathan Cook puts it, IR-Scribe not only meets but exceeds the industry expectations, setting a new standard for beef processing excellence.