Spectral Imaging

New nonvisible LED wavelengths and illuminator designs offer novel methods for revealing hidden image detail, allowing us to identify things that can’t be perceived by the naked eye or traditional imaging. Existing UV and NIR techniques can be augmented with SWIR, multispectral and hyperspectral imaging techniques, and illumination products. SWIR LEDs didn’t exist a few years ago. They are now available, along with InGaAs cameras and quantum dot cameras (QDCs) that enable inspection and sorting in the range of 1,050 to 2,500nm. Hyperspectral imaging generates a hyperspectral stack, with every wavelength included at some step. It provides maximum performance but also with more data and at higher cost. Multispectral imaging systems are better suited for detecting anything from a limited set of variables. Now, multi-band filters and LEDs provide a more practical approach. An example is the use of spectral imaging to analyze where to cut and trim steaks in a meat-processing application. By imaging at different wavelengths it’s easier to distinguish differences in the brightness of the fatty material as well as the bone. With the application of machine vision image processing techniques, it’s less complicated to classify the images and identify the bone, the meat, and the fat. There are two methods for achieving this type of multispectral imaging. The first uses a broad-spectrum light, such as sunlight. The better method involves a multispectral light with the four specific bands of interest built in. This is a much simpler approach for obtaining and analyzing the required images – with much less data, lower cost, and no moving parts. The cost of SWIR imaging has come down dramatically in recent years with advancements in InGaAs and QDC cameras. Additionally, SWIR imaging is ideal for applications that require penetrating and seeing through objects like semiconductor inspection to detect voids or inspect patterning on back sides or to check fluid levels inside high-density polyethylene packaging. With such advancements, the popularity of SWIR imaging continues to grow.

Computational Imaging

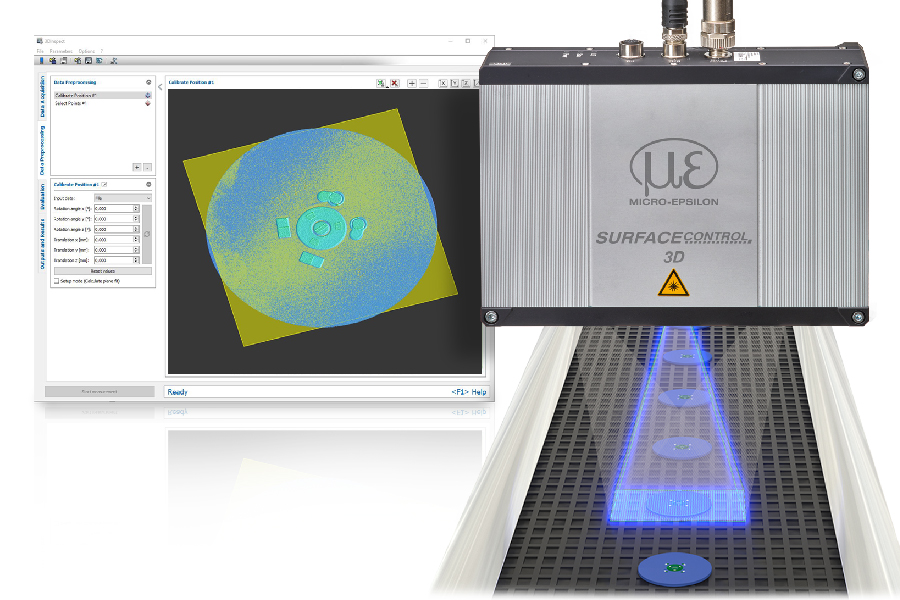

Computational imaging involves using a series of images assembled mathematically to improve image quality and enable feature recognition that’s not possible with a single image capture. This process has been in widespread use for digital photography for quite some time, but it’s seeing increased adoption within machine vision. Common computational imaging techniques include photometric stereo, combining three image planes (red, green, and blue) to make a high-quality color RGB image with enhanced resolution, stacking images to create a deeper depth of field, and high dynamic range imaging (used by cellphone cameras and other smart devices). Multiple image capture with variable lighting is at the heart of computational imaging systems. This means we need controllable lighting managed by a programmable sequencing controller to switch lights at the right time (either between spectrums, directions, or other features) to get the right set of images for the particular computational imaging technique. Image 1 shows the use of photometric stereo to inspect a basketball with a complex surface texture.

www.smartvisionlights.com