This point also highlights an ongoing strategic evolution of the machine vision market. With the increased importance of in-process measurements and the focus on optical and vision-based measurement by traditional metrology companies, the target application space of in-production quality control and quality assurance is identical to that of traditional vision automation suppliers. This development suggests that manufacturing will see an increased convergence between vision inspection and metrology solutions and a greater overlap between metrology companies and automation suppliers.

QIF (Quality Information Framework)

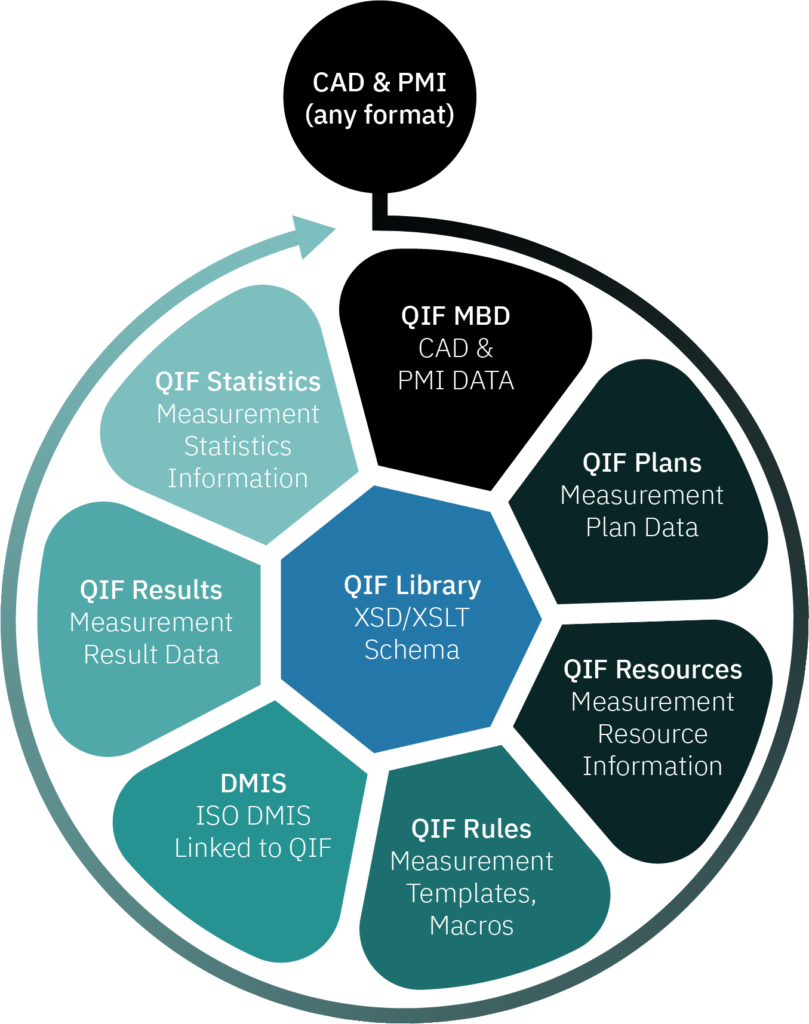

A final topic related to metrology and the digital lifecycle is the relatively recent standard Quality Information Framework. QIF is a global standard that defines a CAD agnostic, XML-based format to define and organise quality information for production. QIF can provide a unified approach to communicating and using measurement plans, measurement results, measurement rules, part geometries, product manufacturing information, as well as statistical analyses. An interesting aspect of the QIF development is that it directly addresses the issue of siloed data from industrial quality processes and seeks to communicate information and results which can be consumed by multiple stakeholders downstream from an original product design, but also to communicate and use the results of quality measurements as they are added to the product record. QIF was first adopted as an ANSI standard in 2013, and recently was converted to an ISO standard ISO23592 in 2020. The standard is hosted by the Digital Metrology Standards Consortium who include many leading metrology and automation companies, suggesting a strong strategic interest in the potential of the standard.

Synthetic Data

The topic of AI is ever present in today’s media and the use of AI/machine learning in vision is a topic with very high visibility. Almost every company in the sector recognizes the importance of AI and are including this into their strategic planning. The conceptual process of a vision AI system uses representative data to train a model, often a neural network, before using this model to provide inferences on unseen data during a run-time inspection. An important aspect of this process is the availability and quality of training data. Without sufficiently representative training data, there is the risk that the model will contain bias or is unable to produce correct inferences in all cases. This problem is exacerbated in a manufacturing context, as image data is often very similar, arising from well controlled processes, and may not contain many examples of defects. Using synthetic data is one approach to addressing the issue of lack of training data and has several attractive aspects. As well as avoiding the need to collect and annotate large amounts of real image data, by directly synthesizing data from 3D scenes, perfect localization and 100% labelling of objects by class or instance can be achieved.

Various toolchains can be used to support this approach, for example the Blender 3D suite is being used by many companies. Blender’s combination of high-quality rendering engines and open Python API in a freely available package is an attractive means to develop a synthetic data approach, particularly for early-stage companies. Under a paid model, the well-established game engine provider Unity, have actively expanded into the industrial arena, providing several products for AR/VR applications, as well as a dedicated synthetic data generation service based on their photo-realistic render engine.

Directly within the industrial sector, Siemens Digital Industries have recently marketed a new service which is intended to directly provide a user with a trained AI vision model based on the user uploading either a CAD model or 3D scan of the part. The solution uses the 3D CAD model to render many synthetic images in the cloud, which are then used to train a dedicated neural network model. Once trained, the model is then provided back to the user for runtime inference at the edge. As the provider of one of the mainstream CAD suites Siemens also has a large exposure to the CAD users and is well placed to develop additional services based on use of CAD models.